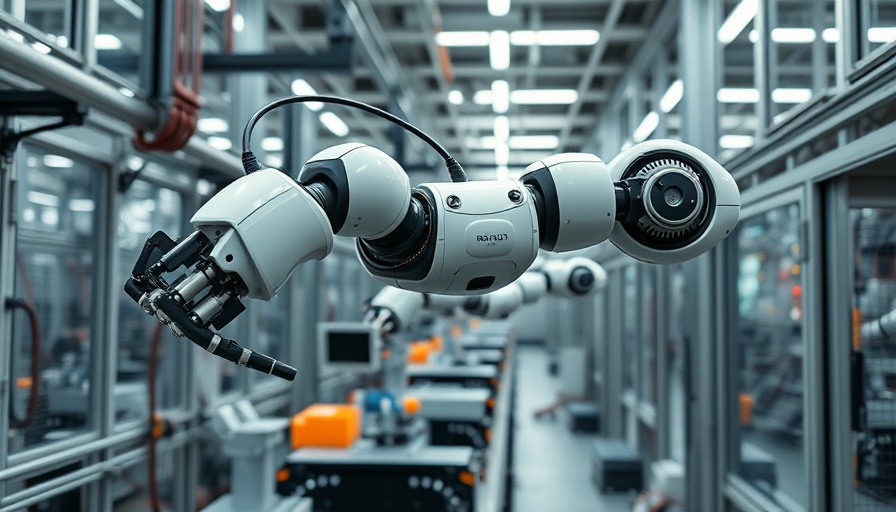

Introduction to AI Innovations in Manufacturing

At the forefront of manufacturing technology, Plataine has unveiled cutting-edge AI agents at the prestigious JEC 2025 event. This release underscores the growing importance of artificial intelligence in revolutionizing production strategies and operational efficiencies. The manufacturing industry is projected to experience remarkable growth as AI integration becomes synonymous with advancement and sustainability.

The Transformative Power of AI in Manufacturing

The AI market in manufacturing is expected to swell from $3.2 billion in 2023 to an impressive $20.8 billion by 2028. This surge reflects a 45.6% annual growth, propelled by the shift to Industry 4.0, where AI-driven automation is increasingly crucial. These AI technologies can prevent equipment failures, optimize supply chains, and ultimately save costs while increasing production output by up to 15%. With advanced AI, businesses can streamline their processes, minimize waste, and enhance sustainability efforts, making them more competitive in a fast-evolving market.

The Role of Generative AI

One of the pivotal trends in manufacturing is the utilization of Generative AI, enhancing how engineers interact with production data. By simplifying complex searches and suggesting design improvements, Generative AI is not only making technology more user-friendly but also instilling sustainable practices in product development. Utilizing AI to simulate variations before producing them leads to reduced material waste, ensuring that manufacturers can meet corporate responsibility goals.

AI-Powered Supply Chain Management

Moreover, AI's ability to analyze mountains of complex data allows manufacturers to spot disruptions before they escalate. The implementation of AI in supply chain logistics means that factors impacting inventory management can be managed proactively, ensuring fewer unforeseen delays. As AI enables predictive maintenance — which reduces downtime by up to 50% — manufacturers can anticipate failures and address potential issues before they arise, significantly boosting productivity.

Real-World Applications of AI in Manufacturing

Companies like Tesla are examples of businesses that are successfully leveraging AI for sustainable manufacturing practices. By using AI models to track sustainability metrics, these organizations can cultivate environmentally friendly operations, enhancing their market appeal. Another illustrative case is Amazon's application of machine learning in logistics, which results in faster deliveries and efficient inventory management. Such cases clearly demonstrate the tangible benefits of AI’s incorporation into the manufacturing ecosystem.

The Advent of AI-Enhanced Digital Twins

The concept of digital twins — virtual models simulating physical systems — has gained traction, with AI powering their evolution. These digital twins allow manufacturers to visualize operations and simulate improvements without physical disruptions, effectively enhancing productivity and reducing resource expenditure.

Why Embrace AI in Manufacturing?

Adopting AI is not merely an operational upgrade; it’s a strategic imperative. The transition to more adaptive systems ensures that manufacturers are prepared for future challenges and disruptions. AI-driven tools provide adaptable frameworks for decision-making and can offer a competitive edge in efficiency, cost-effectiveness, and speed across various manufacturing processes.

Conclusion: The Future of AI in Manufacturing

As we embrace the innovations introduced at JEC 2025, it is clear that AI is not just enhancing manufacturing but is vital for its future. Organizations willing to integrate these technologies will likely lead their industries, benefiting from reduced operational costs and improved sustainability metrics. AI isn't just the future of manufacturing; it is the now. Understanding and implementing these advancements will be crucial for companies seeking to stay ahead in an increasingly competitive landscape.

Add Row

Add Row  Add

Add

Add Row

Add Row  Add

Add

Write A Comment