Beyond Automation: The Promise of AI Agents on Factory Floors

The landscape of manufacturing is witnessing a seismic shift as enterprise AI agents increasingly integrate with operational technology (OT) systems. This marriage brings forth a brand new level of resilience, agility, and efficiency, revolutionizing how factories operate and respond to dynamically changing demands.

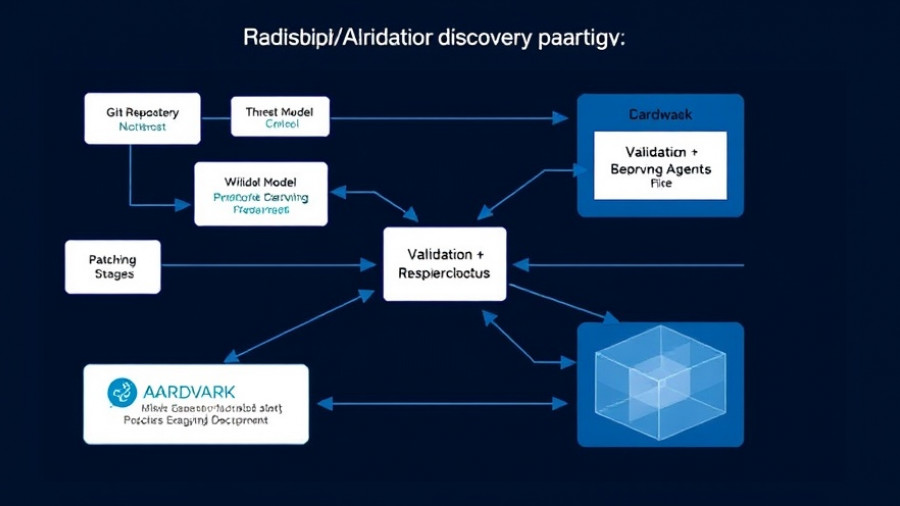

Bridging Two Critical Realms: Operational Technology and Enterprise AI

Enterprise AI enhances data-centric business systems like ERP and customer engagement models. However, its true potential is realized when it converges with operational intelligence systems that monitor and optimize real-time processes across various sectors, including manufacturing and logistics. This integration enables the creation of 'smarter enterprises' capable of rapid decision-making and adaptability to market changes.

The Challenge of the OT-IT Gap and How to Overcome It

Despite the significant benefits, a notable challenge exists—the OT-IT gap. Operational technologies are designed for real-time, physical environments that face demands starkly different from enterprise IT scenarios. Bridging this gap requires innovative strategies to ensure secure, reliable information flow both ways, from physical systems to digital systems and vice versa. For instance, the use of event-driven interfaces and AI-native data strategies can significantly enhance operational functionality while minimizing technical debt.

AI Agents Transforming Production Management

Imagine a manufacturing facility capable of swiftly adjusting its production lines in response to fluctuating demands or supply chain disruptions. Deep reasoning AI empowers systems to monitor inputs continuously, predict issues before they arise, and reallocate resources accordingly. This kind of foresight not only mitigates risks but also optimizes workflows, making factories more productive and reducing waste.

The Future: Resiliency Through Predictive Analytics

Employing AI in OT environments is not merely about integrating technology but rethinking what operational resilience looks like. As organizations build their capacities in anomaly detection and real-time response through deep learning algorithms, they can identify operational disruptions before escalating into costly downtime.

Practical Insights: Embracing the AI Revolution in Industry

For factories eager to harness the power of AI, practical steps include investing in high-quality data collection to enable robust models, fostering collaboration between IT and OT teams, and prioritizing flexibility in existing systems. Partnering with AI-savvy technology firms can provide invaluable insights into developing effective frameworks tailored to their specific environments.

Emotional and Human Considerations: The Workforce of Tomorrow

As AI agents become more integrated into industrial workflows, the human workforce must adapt. This presents opportunities for upskilling, allowing employees to transition from manual roles to strategic oversight positions. Empowering them with the right tools not only enhances job satisfaction but also leverages human expertise to complement AI capabilities.

Conclusion: A Call to Action for Industry Leaders

The integration of AI agents within operational technology environments is not merely a trend but a transformative movement shaping the factories of tomorrow. To stay competitive and innovative, industry leaders must embrace these technologies fully. This journey demands commitment to intelligent design and a passion for leveraging technological advancements. Step into the future and explore how AI can elevate operational excellence in your factory.

Add Row

Add Row  Add

Add

Write A Comment